Antifoam, creating a new era of efficient production!

Antifoam agent has an undeniable importance in industrial production, which effectively improves the air bubble problem in industrial production, and then improves the production efficiency and product quality.

In recent years, the defoamer market has been growing rapidly. in 2018, the global defoamer market size was only $3.2 billion, while in 2022, its size has reached $6.443 billion, and is expected to reach $8.786 billion by 2029, with a compound annual growth rate (CAGR) of 5.16% (2023-2029). Of these, silicone defoamer agent account for a significant proportion, with a share that will reach 44.85%.

Silicone defoamer Have significant advantages

1 / Wide range of applications

As silicone oil is an important component of silicone defoamer, it is insoluble in substances containing polar groups, and not easily soluble in hydrocarbons or organic substances containing hydrocarbon groups. Therefore, silicone defoamer have a wide range of applications, including aqueous and oily systems.

2 / Organo silicone defoamer with high plasticity

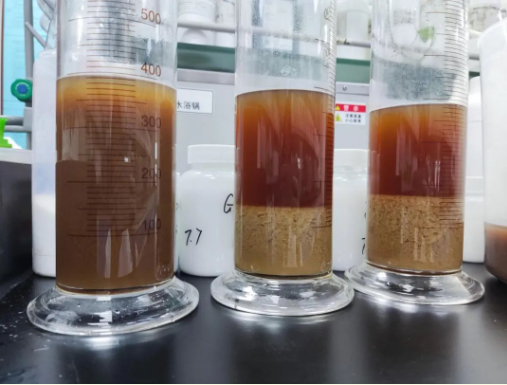

Organo silicone defoamer emulsion is made of silicone paste emulsified by emulsifier, and the quality of silicone paste is crucial to the performance of silicone antifoam agent. The quality of silicone paste is affected by the viscosity of dimethyl silicone oil, hydrophilicity of silica, additives and processing technology.

(In general, the lower the viscosity of dimethylsiloxane oil, the faster the defoaming speed, and the higher the viscosity is the better the effect of foam inhibition; hydrophobic silica can improve the alkali resistance; high temperature and rapid mixing can make the additives are fully mixed, the formation of crosslinks, foam inhibition effect is better.)

Therefore, silicone defoamer can be adapted to different types of foaming liquid and various foaming environments.

3 / Organosilicon defoamer with high defoaming speed

Since the surface tension of silicone oil is generally 20-21dyn/cm, it is smaller than the surface tension of water (72dyn/cm) and the surface tension of general foaming liquid. The smaller the surface tension, the better the antifoaming effect. Therefore, the defoaming speed of organo silicon defoamer is very fast.

4 / Organo silicon defoamer with good stability

Silicone oils are thermally stable and have low intermolecular forces, making them less affected by temperature changes. Therefore, the silicone defoamer can be used in a wide range of temperatures. In addition, the chemical stability of silicone oil is very high, it is difficult to chemical reaction with other substances. As long as the formulation is reasonable, silicone defoamer can be used in systems containing acids, alkalis and salts. In a variety of harsh environments (such as high pH, low pH, high temperature, high pressure, etc.), silicone defoamer can still play a stable antifoaming effect.

5 / Ingredient safety

Silicone oil has been proven to be non-toxic to humans and animals. Its LD50 (half lethal dose) is greater than 34g/kg mouse, which indicates that silicone defoamer can be safely used in the food and pharmaceutical industries.

6 / Low additions

The dosage of silicone defoamer is very low, generally between 1~100ppm, can achieve good defoaming effect. Its small amount of high-efficiency features in line with the concept of many enterprises to reduce costs and increase efficiency.

Based on this, silicone defoamer has been dominant in the market. Of course, the defoaming mechanism of the defoamer is complex and varied, silicone antifoam agent is good, but also to combine with the actual situation of the sample decision, not suitable for all industries.