Water-based defoamers explained!

In industrial production, many harmful foams are often generated, which, if not treated in time, can cause capacity limitations, waste of raw materials, longer production cycles, inaccurate measurement, environmental impact and other problems. In order to deal with the situation, in addition to the use of physical defoaming method, most use the addition of defoamer to deal with.

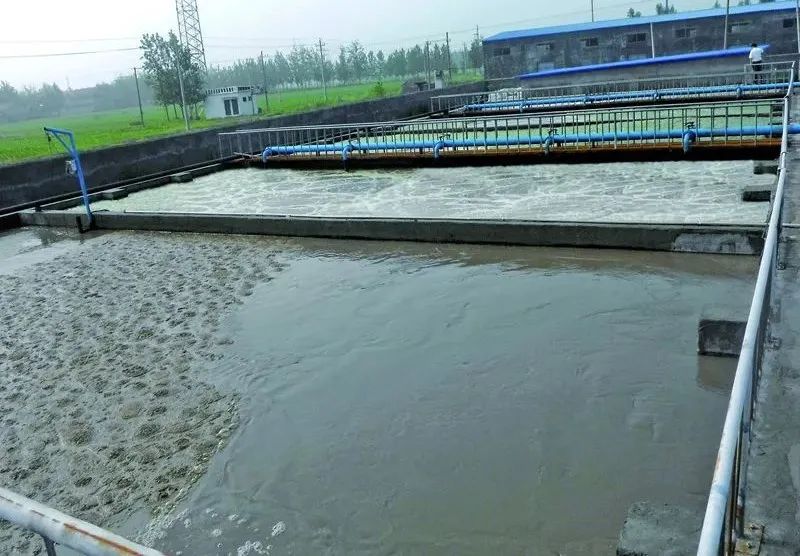

Water-based defoamer has excellent characteristics such as fast defoaming speed, long foam inhibition time, good chemical stability, and a wide range of applications. Water-based defoamer is widely used in petrochemical, metal processing fluid, sewage treatment, fermentation, paper and other fields. We usually contact or understand the water-based defoamer, a wide variety, the next we for water-based defoamer combing, deepen product understanding.

First of all, due to the wide application of water-based defoamer, in the process of application in various fields, in order to facilitate transportation, storage, ease of use and other reasons, defoamer mainly presents the following four forms.

1、Oil type defoamer

Mostly seen as pure silicone products, such as polyether modified silicone oil or the introduction of other functional groups of modified silicone oil, or diluted with organic solvents, generally higher cost of direct use, the effect is not good or because of the presence of solvents affect the environment.

2、Oil paste type defoamer

Appearance is presented as a paste, similar to grease type of paste, easy to transport, easy to store, relatively speaking, when put in need of dilution or added after the transfer of phase.

3、Dispersion type defoamer

Crushed very fine body points dispersed in the insoluble carrier.

4、Emulsion type defoamer

Presenting a milky white viscous liquid, is the most widely used in various industries, the most widely used products, generally for the compounding type products.

Secondly, water-based defoamers can be divided into natural oils and fats, polyethers, silicones (tree esters, modified silicone oil, silicone oil, etc.), high-carbon alcohols, fatty acids and derivatives based on their structure and composition.

After the classification of water-based defoamer, the next combing water-based defoamer other knowledge. In addition to a few pure material products on sale, the market is seen in the products are compounded, the reason is actually relatively simple, defoaming itself from the point of view of the principle of action can be subdivided into bubble breaking, foam inhibition, defoaming three effects, a single substance often does not have all the functions, or there are difficult to enter, slow diffusion, poor spreading and other defects, compounding both to solve the problem, but also to avoid the complex chemical reaction.

Then, we follow the above ideas, discuss the defoaming products need to consider several points of focus: 1.

1, the volatility of water-based defoamer can not be too strong, otherwise the action time will be greatly shortened.

2, defoamer on the foaming medium can neither be too affinity, nor completely insoluble, otherwise the amount is too large or easy to separate.

3, the surface tension of the defoamer needs to be lower than the foaming medium.

4, water-based defoamer can not react with the foaming medium, good chemical stability.

5, defoamer needs to meet the whole process of the foaming medium, can not be in the process of temperature rise / fall, rise / fall pressure, PH value changes in the short-term failure.

6, need to have other required matters, such as storage of short-term non-separation settlement, high efficiency of defoaming, good dispersion, etc..