Why is defoamer an indispensable part of cutting fluid?

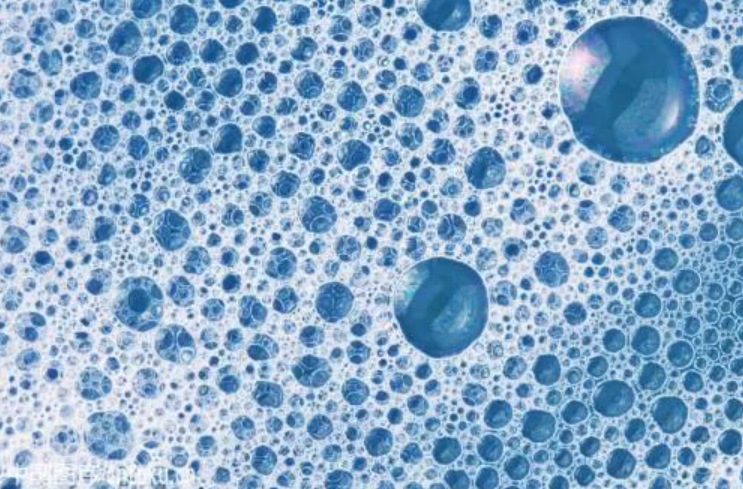

Due to the continuous squeezing and friction of metal during the cutting process, a large amount of heat is generated. Therefore, everyone chooses to use cutting fluid to reduce the temperature and friction during metal cutting. However, the cutting fluid contains a large amount of surfactant, which leads to strong foaming performance of the cutting fluid. In addition, the working fluid flow rate is relatively fast during metal processing, which will produce strong foam during metal processing. At this point, the effect of defoamer becomes apparent, which can effectively prevent the loss of cutting fluid and reduce usage costs.

Reasons for foaming in metal cutting fluid

1. The liquid level of metal cutting fluid is too low.

2. The flow rate of metal cutting fluid is too fast, and bubbles do not overflow all the time. The more they accumulate, the more foam occur.

3. There are too many right angles in the sink planning, or the nozzle viewpoint of the metal cutting fluid is too straight.

4. Metal cutting fluid contains a large amount of surface active dose.

5. The water quality is too soft, resulting in too much foam.

6. Often caused by external influences, such as contamination of cutting fluid by cleaning agents, infiltration of impurities, etc.

The hazards of foaming in metal cutting fluid

1. foam will affect its lubrication and cooling effects.

2. The foam increases gas-liquid contact, promotes oxidation, and produces flotation, which makes the ingredients mixed unevenly, thus leading to product deterioration

3. The foam will affect the normal operation of the machine. The oil tank is filled with foam and overflows, causing the oil level to drop, damaging the components, destroying the uniform supply, and affecting the stability of the operation

4. foam will affect the antirust performance, cleaning performance and extreme pressure performance of the product.

5. foam will affect the transmission power and signal of the product

Advantages of metal cutting fluid defoamer

1. The defoaming agent has strong defoaming and anti foaming effects, with a small dosage, and does not affect the basic properties of the foaming system.

2. Defoamer and antifoam have good diffusion and permeability, and can be completely compatible with oil and cutting fluids.

3. Metal cutting fluid defoamer has good heat resistance, stable chemical properties, and are non corrosive, non flammable, and non explosive.

4. Cutting fluid defoamer can be used in acids, bases, salts, electrolytes, and hard water.