Defoamer Antifoam: The Foam Killer Behind the Industry

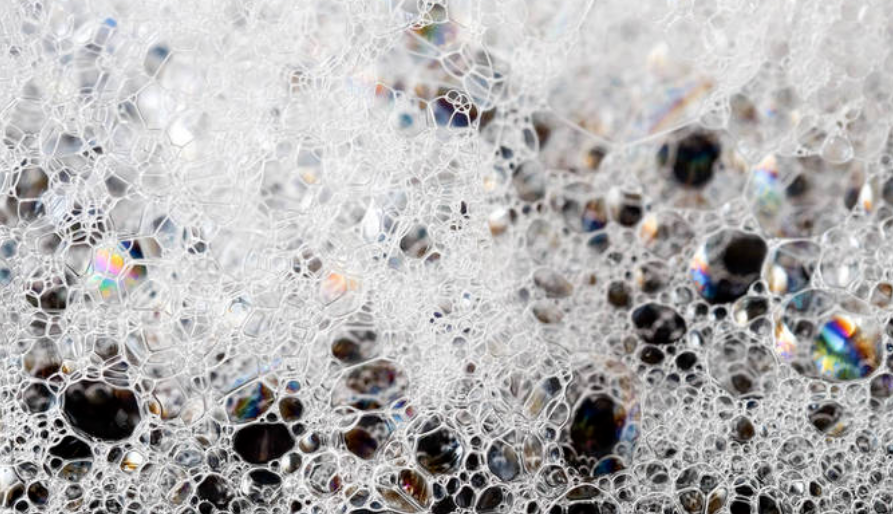

“In the world of chemical production, a seemingly insignificant amount of bubbles can cause a host of serious problems. Imagine a large chemical reactor where a variety of chemicals are reacting vigorously and suddenly a large number of bubbles appear. These bubbles not only occupy the reaction space, but also reduce the efficiency of the reaction, making what should be an efficient, slow and difficult process. In the face of the “crisis” brought about by these bubbles, defoamer antifoam have emerged as the key to solving the foam problem.”

Defoamer Antifoam - the “savior” of foam problems

Defoamer Antifoam, as the “savior” that specializes in dealing with foam problems, play an indispensable role in industrial production. Simply put, an antifoam agent is a chemical additive that can reduce the surface tension of a liquid, thereby eliminating or inhibiting the generation of foam . Its main role includes two aspects of defoaming and foam inhibition. Defoaming, is to quickly eliminate the foam that has been produced; foam inhibition, is to prevent foam from being produced again within a certain period of time.

Wide Range Of Applications For Defoamer Antifoam

In practical application, there are many types of defoamer antifoam, and different types of defoamers are suitable for different industries and scenarios. For example, silicone defoamer antifoam has excellent defoaming performance and chemical stability, widely used in coatings, inks, textiles and other industries; polyether defoamer antifoam is excellent in papermaking, food fermentation, water treatment and other fields; mineral oil defoamer is commonly used in petroleum extraction, metal processing and other industries. In short, defoamer antifoam with its unique action mechanism and diverse types, to solve the foam problem in industrial production to provide an effective solution.

In the pulp and paper industry, a large number of foams are generated in the pulping and paper making process. These foams will affect the quality of paper, such as holes, uneven thickness and other problems, but also reduce production efficiency. Defoamer antifoam can quickly eliminate the foam in the pulp, improve the uniformity and strength of the paper, to ensure the efficient operation of the papermaking process.

In the chemical field,defoamer antifoam is indispensable for the production of synthetic resins, coatings and inks, as well as for the processing of rubber and plastics. Take the production of coatings as an example, defoamer antifoam can eliminate the foam generated in the process of mixing and dispersion of coatings to ensure the uniformity and stability of coatings, so that the surface of the coating is smooth and flat, and enhance the decorative and protective properties of coatings. In the ink production, defoamer antifoam can effectively avoid the foam on the ink fluidity and printing quality, to ensure that the printing pattern is clear and exquisite.

The oil and gas industry is also inseparable from the defoamer antifoam. In the process of oil extraction, the natural gas overflow in the formation and the addition of various chemical additives can easily lead to a large number of foam. These foams not only reduce the efficiency of oil extraction, but also may cause equipment failure. The addition of defoamer antifoam can quickly eliminate the foam and ensure the smooth progress of oil extraction. In the oil and gas pipeline, defoamer antifoam can prevent bubbles from adhering to the pipeline wall, reduce the risk of pipeline clogging, and ensure the stable delivery of oil and gas.

ARE YOU STRUGGLING WITH FOAM ISSUES?

CONTACT AND TELL US ABOUT YOUR INDUSTRY FOR A PROFESSIONAL FOAM SOLUTION!