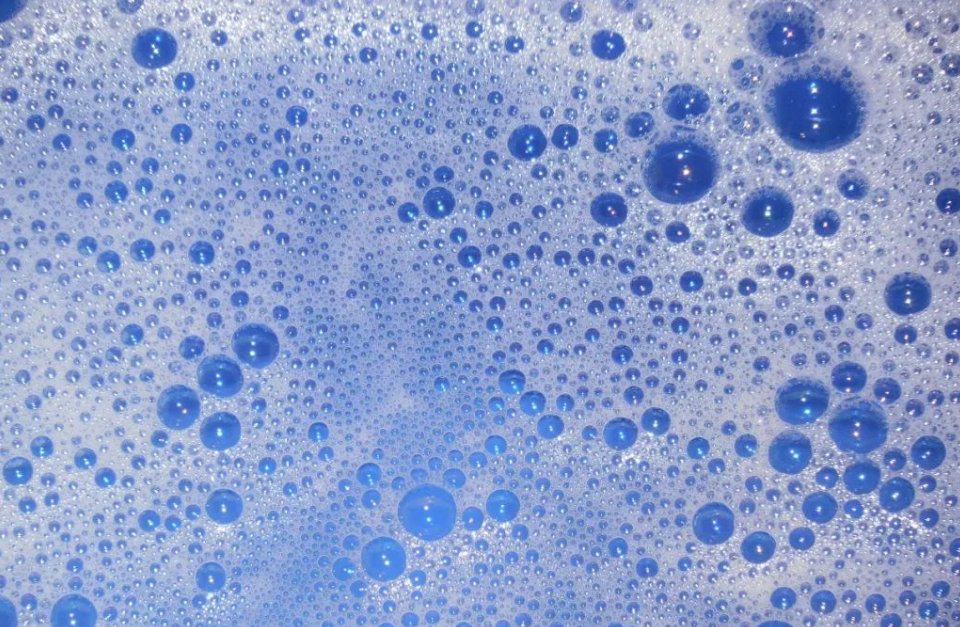

Introduction and Characterization of Silicone Defoamer

Silicone defoamer is a natural resource with renewable characteristics, known as “oil on the tree”, widely used in paints, silicone defoamer soap, food and medicine, paper, ink color carrier, adhesives, fluxes, electrical appliances, pesticides, spices and cosmetics and other industries.

Silicone Defoamer Classification

According to the formulations are divided into three categories: body-type organosilicon defoamer, emulsion-type organosilicon defoamer, solid-type silicone defoamer (organic carrier type, inorganic carrier type)

(a) The body-type silicone defoamer: mainly composed of silicone defoaming active ingredients, in the aqueous system can be dispersed and does not contain water defoamer.

(b) Emulsion-type silicone adefoamer silicone defoaming active ingredients made by emulsification, in the aqueous system can be dispersed in the oil-in-water emulsion defoamer.

(c) solid-type silicone defoamer: the use of organic materials such as starch or inorganic salts and other inorganic substances, through the adsorption of silicone antifoaming active ingredients made of solid-form defoamer.

Silicone Defoamer Features:

1. Silicone defoamer can de-foam efficiently, can eliminate a large number of foam in a short time.

2. Silicone defoamer has good stability: it can maintain stability in extreme environments such as strong acid and strong alkali.

3. Silicone defoamer has a wide range of applications: applicable to a variety of liquids, including aqueous, oily and solvent-based liquids.

4. Silicone defoamer is easy to use: just add it to the liquid that needs to be defoamed. -Note that silicone defoamer is easy to emulsify and delamination: in the process of using it, you need to pay attention to the reasonable selection in order to avoid delamination phenomenon.

Free samples for a limited time!