Pulp foaming? Papermaking industry defoamer to help you

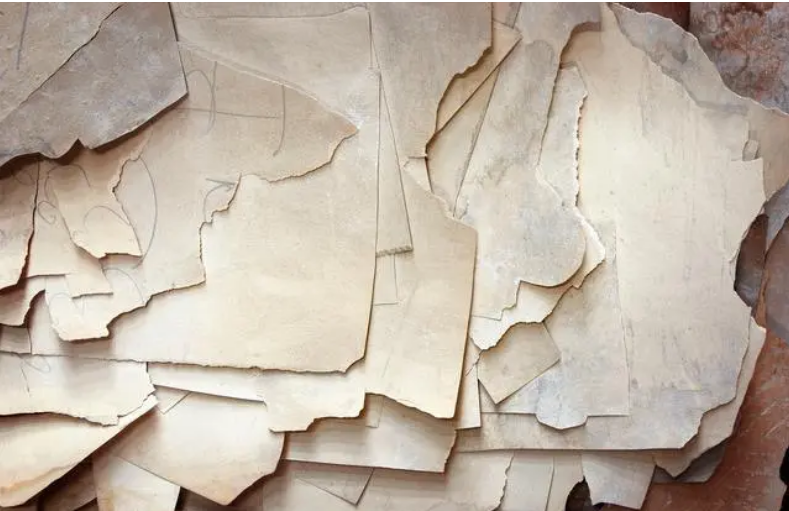

In life, the huge scale of paper use always makes people think that the manufacture of paper is very simple. But in fact, in the paper-making process, there are many difficulties, such as the emergence of foam makes the paper-making process can not be carried out smoothly, and even affect the quality of the subsequent finished products. Generally encountered in this situation, the industry is inclined to use defoamer to solve the problem of foam in the process. That papermaking defoamer is what exactly? Defoamer can be applied in which link?

Papermaking defoamer is designed to address the problem of paper production foam, mainly with special silicone polyether and good dispersion of chemical additives, this chemical composition is stable, non-toxic pollution, no negative impact on the human body after adding. And papermaking industry defoamer for different aspects of the defoaming needs and effectiveness, with good defoaming and foam inhibition performance on the basis of defoamer does not produce adverse chemical reactions with other chemical additives, which will not change the color of the pulp and paper, the strength of the performance of the product will not be affected, so the papermaking industry defoamer is widely used in all aspects of the paper industry.

Paper defoamer is mainly used in two parts of the papermaking process: pulp washing and paper copying.

In the pulp washing process, foam makes bleaching, cleaning and conveying processes can not be carried out smoothly, thus reducing production efficiency. At this stage, defoamer plays a major role in defoaming, eliminating fatty acid soap and other foaming substances in the slurry. Paper industry defoamer has excellent water solubility, can quickly disperse and evenly distributed in the pulp, so as to quickly eliminate foam, reduce the number of foam, has been to enhance the efficiency of the purpose.

In the paper copying process, the most important function of defoamer is to inhibit the generation of foam. Foam generation can greatly reduce the uniformity of paper forming, cause pinholes, and cause paper breakage and other problems. At this stage, the papermaking defoamer penetrates deep into the paper fibers, by removing the fine bubbles between the fibers, dissolving the air inside the pulp, and forming an elastic film on the liquid surface, so as to achieve the effect of long-term foam inhibition, making the finished paper beautiful quality.

Contact for professional solutions about papermaking foam.