Scale inhibitors should not be underestimated - to ensure the stable operation of reverse osmosis systems

After scaling pollution occurs in the reverse osmosis system, it usually manifests as a decrease in water production, a decrease in desalination rate, an increase in operating pressure, and an increase in section pressure difference. Scaling usually occurs first in the last stage of the membrane element, and then gradually spreads forward. Raw water containing calcium, bicarbonate, or sulfate ions may clog the membrane system within a few hours due to scaling. Scaling containing barium and fluorine generally forms more slowly because their common raw water concentrations are usually lower.

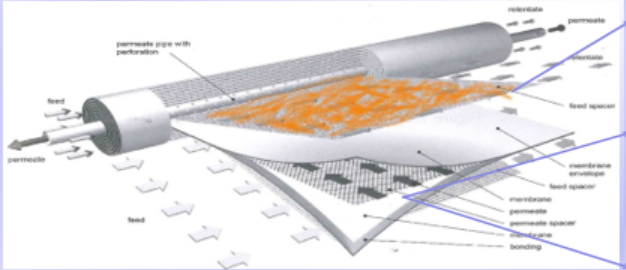

By disassembling the last branch membrane element at the end of the end section, scaling substances can usually be observed at the end face of the membrane element, the end plate of the membrane shell, etc. After the membrane element is weighed after water control, the weight of the membrane element will be significantly increased than that of the new membrane (the weight of the new membrane element is generally about 13.5KG).

Dissect the final membrane element and analyze the scaling material on the membrane surface. The crystal structure of the sediment can also be observed under a microscope. Chemical analysis or X-ray analysis can identify the type and substance of scaling.

It is necessary to take targeted and effective prevention and control measures according to different types of water sources. Common prevention and control measures include pre-treatment, acid adjustment of pH, addition of scale inhibitors, pre-treatment to remove or reduce insoluble salts (such as resin softening for hard removal, chemical softening for hard removal, silicon removal, iron and manganese removal, etc.).

When the solubility product of insoluble salts on the concentrated water side in the reverse osmosis system reaches or exceeds saturation, adding scale inhibitors is the most commonly used scale inhibition measure. The correct selection and dosage of scale inhibitors are crucial.

Selection of corrosion and scale inhibitors

Currently, most of the corrosion and scale inhibitors for reverse osmosis provided by legitimate manufacturers in the market are organic acid salts and polyacrylic acid salts, which have good scale inhibition effects. Organic scale inhibitors may precipitate with cationic polyelectrolytes or multivalent cations (such as Fe and Al) used for coagulation in pre-treatment, causing pollution, so excessive use should be avoided. When adding anionic scale inhibitors, it is important to avoid adding or over adding cationic polymers in the pre-treatment process to prevent precipitation.

Regardless of which brand and model of corrosion and scale inhibitor is selected, it is necessary to provide raw water quality analysis data and design parameters of the reverse osmosis system to ensure that the corrosion and scale inhibitor matches the actual operating conditions.

System maintenance recommendations

(1) In the daily operation process, a detailed operation ledger should be recorded, instruments should be calibrated regularly, and the output of calibrated metering pumps should be checked.

(2) Each team checks the liquid level of the corrosion and scale inhibitor tank to ensure normal dosing, and calculates the dosing concentration based on the treated water volume.

(3) Carry out data monitoring and regularly organize preventive cleaning.

(4) Discovering abnormal data, stopping the machine in a timely manner, investigating the cause, and organizing targeted chemical cleaning.

(5) When adjusting the operating conditions of the reverse osmosis system (especially when adjusting the parameters of water production and recovery rate), the feasibility of the adjustment should be confirmed first, and the dosage of corrosion and scale inhibitor should be adjusted accordingly.