Sewage treatment defoamer, do you know how to choose?

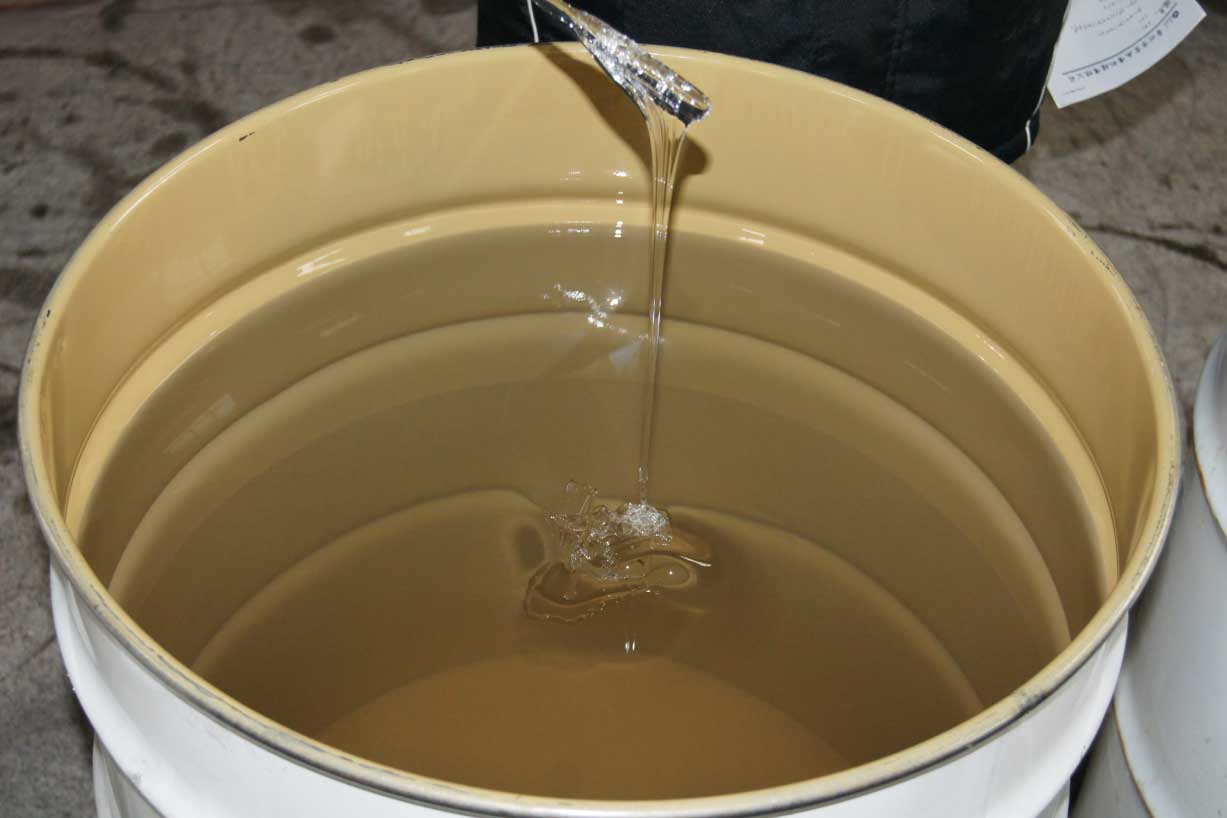

Foam problems in water treatment troubled a lot of people, debugging the initial foam, surfactant foam, impact foam, peroxide foam, circulating water treatment by adding non-oxidizing biocides generated by the foam and so on, so the use of antifoam in water treatment is relatively common, this article comprehensively introduces the principle of antifoam agent, classification, selection and dosage!

Foam elimination methods

1、Physical methods

From the physical point of view of the elimination of foam methods mainly include the placement of baffle or screen, mechanical mixing, high-speed centrifugation, pressurization and decompression, high-frequency vibration, and ultrasonic (acoustic liquid control) and so on. However, the common disadvantage of these methods is that the use of environmental factors by the strong constraints, defoaming rate is not high, the advantage of environmental protection, high reuse rate.

2、Chemical methods

Eliminate foam from the chemical point of view of the method mainly includes chemical reaction method and add defoamer method. Chemical reaction method refers to the chemical reaction with the foaming agent by adding some reagents to generate insoluble substances, thereby reducing the concentration of surfactant in the liquid film, prompting the rupture of the foam, but this method exists foaming agent composition is uncertain, producing insoluble substances on the system equipment to produce hazards and other shortcomings. Nowadays, the most widely used defoaming method in various industries is the method of adding defoamer, the biggest advantage of this method lies in the high efficiency of bubble breaking, easy to use and other advantages, but finding a suitable and efficient defoamer is the key.

Classification of defoamers

Commonly used defoaming agent can be divided into silicone defoamer, surfactant defoamer, alkane defoamer and mineral oil defoamer according to different components.

1、Silicone defoamer

Silicone resin antifoam agent is also known as emulsion-type antifoam agent, the use of silicone resin with emulsifier (surfactant) emulsification dispersed in water and then added to the wastewater. Silicon dioxide powder is another silicone antifoam agent with good defoaming effect.

2、Surfactant defoamer

This kind of antifoam agent is actually an emulsifier, that is, the use of surfactant dispersion effect, so that the formation of foam in the water to maintain a stable emulsion state dispersion, so as to avoid generating foam.

3、Chain alkane antifoam agent

Chain alkane antifoam agent is an emulsifier to chain alkane wax or its derivatives emulsified and dispersed made of antifoam agent, its use and surfactant emulsified antifoam agent similar.

4、Mineral oil defoamer

Mineral oil is the main antifoaming component. In order to improve the effect, sometimes mixed with metal soap, silicone oil, silica and other substances used together. In addition, in order to make the mineral oil easy to diffuse to the surface of the foaming liquid, or to make the metal soap and other uniformly dispersed in the mineral oil, and sometimes can be added to a variety of surfactants.

Advantages and disadvantages of different types of defoamers

1. Mineral oil defoamer

Mineral oil antifoam agent is amide, low-grade alcohols, fatty acids and fatty acid esters, phosphate esters and other organic antifoam agent research and application of early, belongs to the first generation of antifoam agent. Mineral oil antifoam agent has the advantages of easy to obtain raw materials, high environmental performance, low production cost, etc.; the disadvantage lies in the low defoaming efficiency, specialization, harsh conditions of use.

2. Polyether antifoam agent

Polyether antifoam agent is the second generation of antifoam agent, mainly including straight chain polyether, alcohol or ammonia as the starting agent of polyether, end group esterification of polyether derivatives of three. The biggest advantage of polyether antifoam agent is that it has strong anti-foaming ability, besides, some polyether antifoam agents have excellent performance such as high temperature resistance, resistance to strong acid and alkali, etc.; the disadvantage is that the conditions of use are restricted by the temperature, the field of use is narrow, the anti-foaming ability is poor, and the rate of breaking the bubble is low.

3. Organosilicon defoamer

Organosilicon antifoam agent (the third generation of antifoam agent) has strong defoaming performance, fast foam breaking ability, low volatility, non-toxic to the environment, non-physiological inertia, the use of a wide range of advantages, so there is a wide range of prospects for application and a huge market potential, but the foam inhibition performance is poor.

4. Polyether modified polysiloxane defoamer

Polyether modified polysiloxane antifoam has the advantages of both polyether antifoam agent and organosilicon antifoam agent, which is the development direction of antifoam agent, and sometimes it can be reused according to its reverse solubility.

Contact Our Foam Control Team To Get Recommendations For Specific Foam-control Solutions.