The role and principle of silicone polyether defoamer knowledge points!

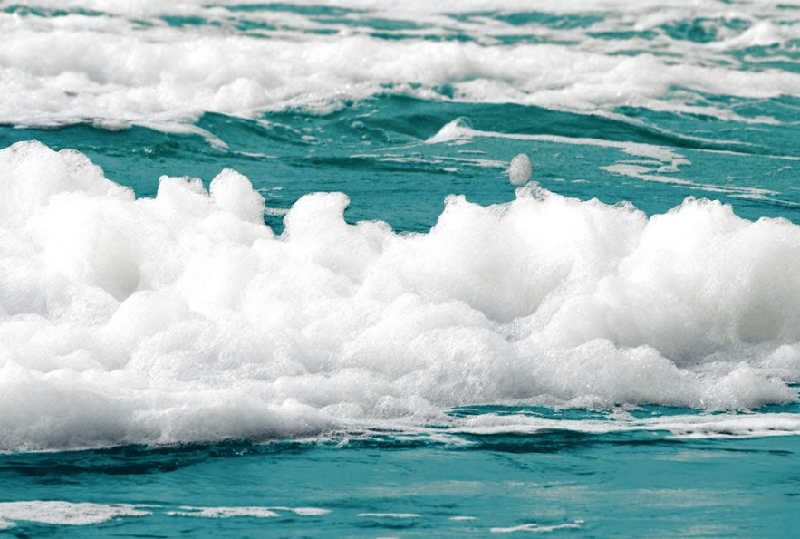

The presence of foam in most industrial processes can adversely affect production. The addition of defoamer is an effective and economical way to eliminate harmful foam. Silicon polyether defoamer is a new type of defoamer that combines the advantages of polyether and silicone defoamer. It is composed of a variety of chemical additives, such as carriers, emulsifiers, dispersants, etc., to enhance its dispersion effect and stability, make the defoaming speed faster, and have broad application prospects.

Silicon polyether defoamer has strong defoaming effect, good heat resistance, shear resistance and acid and alkali resistance. In addition, the antifoam has the advantages of stable storage and convenient use, so the silicon polyether antifoam is widely used in various occasions. Especially for defoaming under harsh conditions, such as high temperature and strong acid and alkali environment and defoaming in fermentation process. And the hydrophobicity and hydrophilicity of the antifoam just meet the defoaming standard, so that the defoaming agent can contact the foaming liquid in a wide range and quickly diffuse into the entire foaming system.Defoamer can play the role of preferentially occupying the surface of the foam liquid film. Therefore, the anti-foaming and defoaming effects are very good. Even if the added amount is small, the defoaming is still very fast. After adding the silicon polyether antifoam for about 15s, the foam can be completely eliminated without residue.

The defoaming principle of the active ingredient of silicone polyether defoamer:

When the silicone polyether defoamer is used, the defoamer can directly enter the foam liquid film, forming a bi-concave oil film on its surface. Since the surface tension of the defoamer is much smaller than the surface tension of the foam liquid film, the defoamer can continue to diffuse and penetrate between the liquid films, and its penetration depth continues to expand, thereby replacing the original liquid film and forming a "water-oil- Water" bridge. The "bridge" is radially pulled by the liquid with high surface tension on both sides, and will continue to become thinner and thinner. This eventually leads to a stress imbalance and causes the bubble to burst. The defoamer particles that are insoluble in the system can quickly re-enter the surface of another foam film and continue to repeat the above steps. until all foam disappears. The whole defoaming process lasts for a few seconds and is very fast, so it is also called a fast and efficient defoamer.