The role of defoamers in drilling muds

The role of defoamer in the mud as the name suggests is to eliminate the bubbles generated in the drilling fluid, but due to the foaming system and the use of different conditions, the defoamer used is not the same, in order to meet the needs of a variety of needs, should be produced in a variety of varieties, the nature of the defoamer is different. Antifoam agent in its physical and chemical properties should meet the following conditions:

1. Oil field drilling defoamer on the foaming system has a highly effective defoaming effect, lower surface tension than the foaming medium, insoluble in foaming medium, and not subject to the foaming system to increase the capacity and the effect of degradation;

2. Oil field drilling chemical defoamer is inert to the foaming system, no chemical reaction, no side effects on the final product, does not affect the product performance and appearance;

3. It should also meet the special conditions of drilling process, such as pH value and temperature requirements;

4. Defoamer for drilling fluid is easy to use , easy to handle, has good storage stability, long-term storage without deterioration, safe for humans, animals and the natural environment.

Foam formation conditions

The prerequisite for the formation of foam is that there must be mutual contact between gas and liquid. The contact between gas and liquid can be achieved through three ways: first, directly to the liquid into the foreign gas; second, the use of gas wells within the gas flow stirring; third, the additives in the drilling fluid under certain conditions to react to produce insoluble gas.

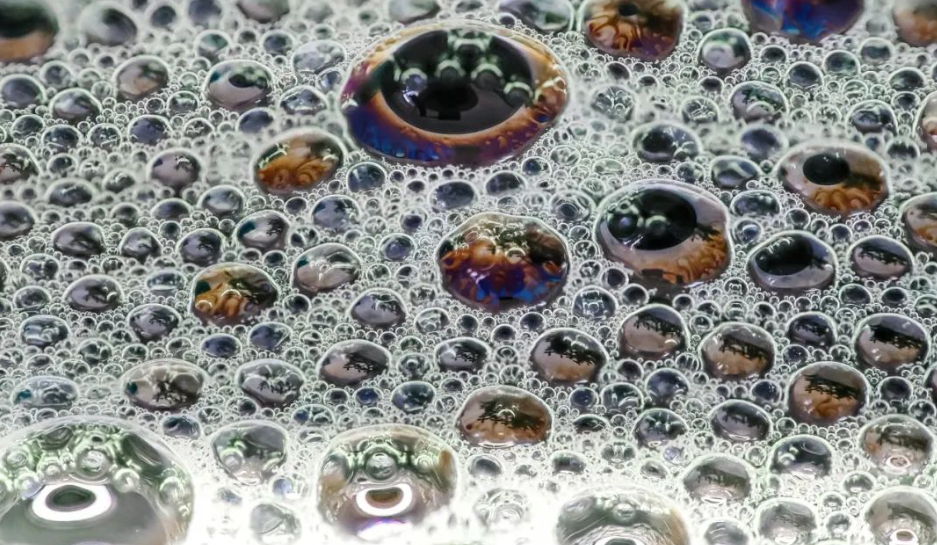

Foam can be produced by stirring or blowing on soapy water. Close observation reveals that foam is a system of many bubbles separated by a liquid. On the surface, foams and emulsions appear to be separated by a film of liquid, but there is a big difference in nature. Emulsion is a liquid is another immiscible liquid separated, while the foam is a gas dispersed in the liquid dispersion system, the gas is dispersed phase (discontinuous phase), the liquid is a dispersed medium (continuous phase). Due to the great difference between the density of gas and liquid, the bubbles in the liquid always rise to the liquid surface very quickly, forming a small amount of liquid film composed of bubble aggregates, that is, usually called foam.

In a nutshell, defoamer refers to the chemical and interfacial chemical defoaming agent. Antifoam “inhibit foam”, “break foam” process is: when the system to join the antifoam agent, its molecules disorganized widely distributed in the liquid surface, inhibit the formation of elastic film, that is, to terminate the generation of foam. When a large number of foam system, add antifoam agent, its molecules immediately dispersed in the foam surface, rapid spreading, the formation of a very thin double film layer, further diffusion, infiltration, laminar invasion, thereby replacing the original foam thin wall. Because of its low surface tension, it will flow to the high surface tension liquid that produces foam, so that the low surface tension antifoam agent molecules in the gas-liquid interface between the continuous diffusion, infiltration, so that the membrane wall is rapidly thinning, the foam at the same time by the surrounding surface tension of the membrane layer of the strong traction, so that the foam around the stress imbalance, which leads to the “bubble bursting This leads to the stress imbalance around the foam, thus leading to its “bubble bursting”. Defoamer molecules insoluble in the system, and then re-enter the surface of another foam film, and so on, all the foam, all overthrow.