The secret to eliminating large amounts of foam in oilfield extraction - defoamer & antifoam

Talking about the impression of foam, it is like the seasonal beer foam, both such that foam is needed, and foam generated in each manufacturing process, foam generated in manufacturing, which is going to affect the manufacturing operation, and this kind of foam is not needed for us.

First of all, I would like to ask what is the definition of a bubble and how is it formed?

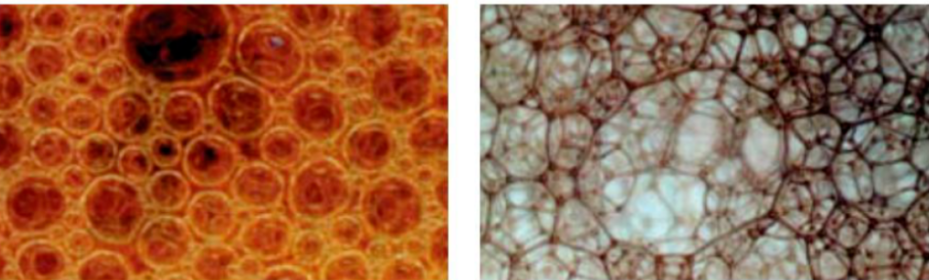

“Foam” is defined as a fine gas dispersed in a liquid layer, usually air and characterized by a liquid-gas interface with a large impact, known as a lamellar thin liquid layer surrounded by the presence of air, which one or more bubbles stick together state is called “foam”. Foam” is the state in which one or more bubbles stick together.

In order to stabilize this foam, stabilizing substances are needed. Stabilizing substances are substances that are active at the interface and are characterized by the presence of hydrophobic and hydrophilic parts in the molecule, such as surfactants, as a representative example. Substances with such a structure have the tendency to be oriented at the liquid-air interface, and have the effect of lowering the interfacial tension, which is an important reason for stabilizing the foam.

In many production processes, foam can cause a lot of trouble. Elimination of harmful foam can be accomplished by using methods such as standing, depressurization (vacuuming), heating or pressurization. However, when it is necessary to eliminate foam quickly and effectively in a short period of time, it is important to use a foam stabilizing substance in any case, together with an antifoam agent to prevent foam from being generated, and to promote the bursting of the generated foam as soon as possible.

Mechanism of action of defoamer

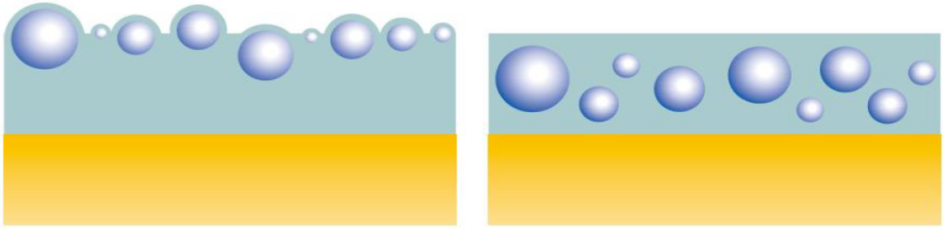

Antifoam agent is in the form of particles infiltrated into the foam system, when the foam to produce, the presence of defoamer particles in the system can quickly destroy the elastic membrane of the bubbles, inhibit the production of foam. If the foam has been produced, add the antifoam agent contact foam, that is, capture the foam surface of the hydrophobic chain end, by rapid spreading, the formation of a very thin double film layer, further diffusion, laminar invasion, replacing the original foam membrane wall. Defoamer antifoam itself has a very low surface tension, can make the part of the bubble membrane containing antifoam agent membrane wall gradually thin, and is surrounded by a large surface tension of the membrane layer of strong traction, the whole bubble will produce an imbalance in the stress, resulting in the rupture of the bubble.

Defoamer must be easy to spread on the solution surface of the liquid, defoamer into the foam bimolecular oriented membrane, destroying the mechanical balance of the oriented membrane and play the effect of breaking the bubble. Antifoam agent in the solution surface spread faster, the liquid film becomes thinner, quickly reach the critical thickness, foam destruction accelerated, defoaming effect is strengthened, the performance of excellent antifoam agent must both defoamer and foam inhibition, it not only can make the foam quickly burst, but also in a fairly long time to prevent the generation of foam.

Oilfield defoamer, easy to defoam

How important oil is to a country, it is self-evident, but the extraction of oil is quite complex, in the process of oil extraction often appear many problems, foam is one of the problems, crude oil in the extraction and processing, due to the temperature, pressure, flow rate, section of the plug flow and other factors, the gas-liquid equilibrium of the crude oil is broken, light hydrocarbons from the crude oil to escape and form bubbles.

The presence of bubbles makes the pipeline transportation fluctuations in the multiphase flow, causing instability in the pipeline production and liquid transportation, and at the same time, it will reduce the effective separation space in the equipment, and it may also make the gas phase carry oil droplets into the natural gas treatment system, so that the flare combustion is insufficient to appear in the condition of black smoke, etc., a large number of foam will make the process of extraction is more difficult, and it will also reduce the quality of the oil product, in order to eliminate or reduce the foam, it will generally be in the In order to eliminate or reduce foam, oilfield defoamer is generally injected into the oil field facilities.

Due to the special operating environment of oilfield, compared with the traditional antifoam agent, polyether modified organosilicon defoamer is more and more favored by everyone, oil field drilling defoamer can maintain good stability in the system, with excellent high temperature performance. Suitable for oilfield antifoaming applications, can also be used for mud, mortar, sulfonated asphalt, humic acid, mineral processing, such as a variety of poor system of foam elimination, it can be quickly dissolved in water, can be used alone, can be used in conjunction with other agents; good stability, does not break the emulsion oil bleaching phenomenon, there is no precipitate; the same oilfield defoamer is also effective for non-aqueous systems, so the application of the oilfield environment has a very good effect.