Glutamic Acid Defoamer

- RISE

- Liaoning, China

- 7days

- 50mt/Month

*EXTREMELY STABLE, NO EFFECT ON MICROORGANISMS

* RESISTANT TO STRONG ACID AND ALKALI, WITHOUT ANY SIDE EFFECTS

*EASY TO DIFFUSE, GOOD PERMEABILITY AND DISPERSION

* STRONG DEFOAMING ABILITY, LONG-LASTING

Causes of foaming in glutamic acid fermentation

1. The fermentation process heats up too fast.

2. The surface tension of the fermented raw materials is large, and it is easy to foam.

3. The lysis of the thalline, the albumin of the thallus is released in large quantities, causing rapid foaming.

4. Blistering caused by the decomposition of bacterial activity to produce carbon dioxide and other substances.

5. Caused by ventilation and stirring, the greater the ventilation volume and the more vigorous the stirring, the more foam.

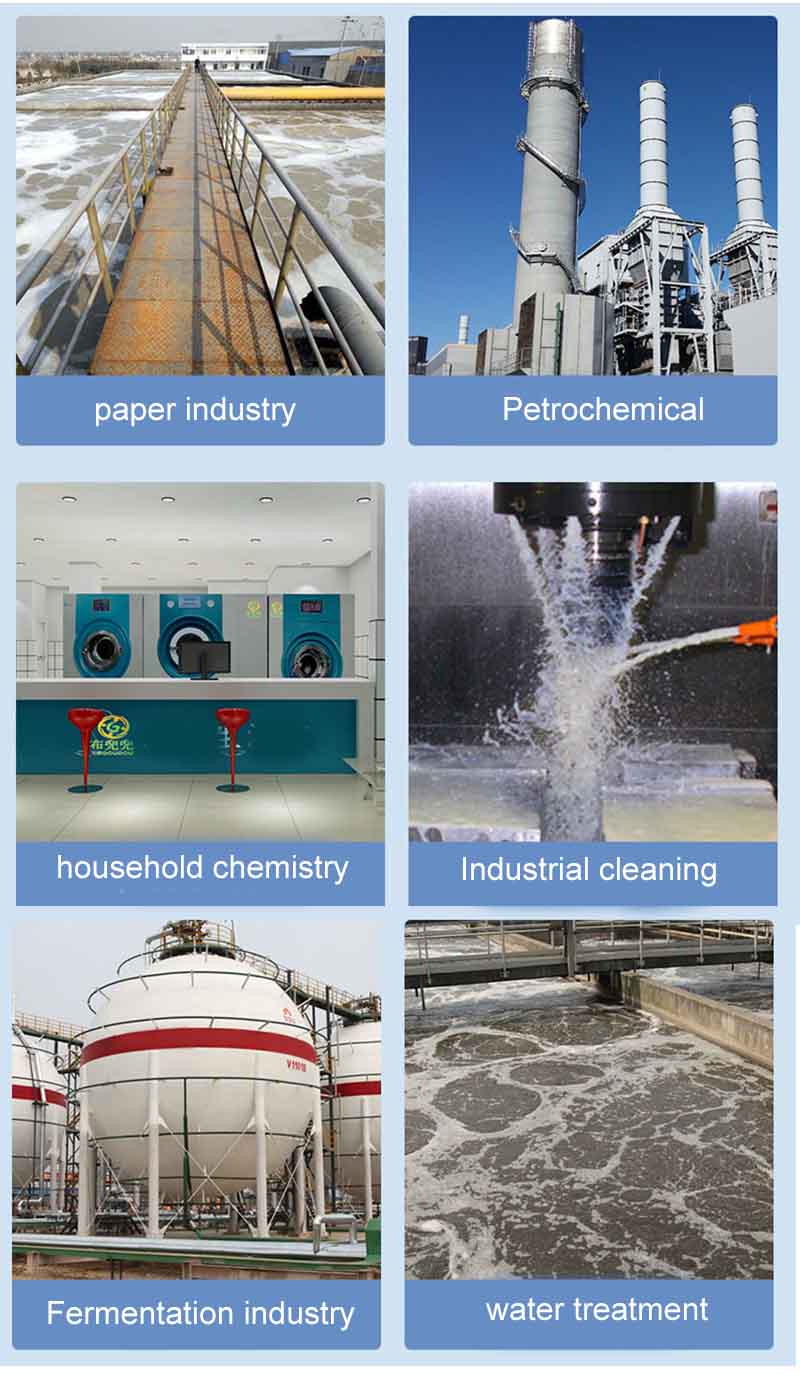

Application of glutamic acid defoamer

Glutamic acid fermentation defoamer is widely used in: fermentation processes such as biomedicine, antibiotics, xanthan gum, alcohol, yeast, enzymes, streptomycin, glutamic acid, monosodium glutamate, soy protein, citric acid, abamectin, Jinggangmycin, Gentamicin, kanamycin, various amino acids and vitamin C industries.

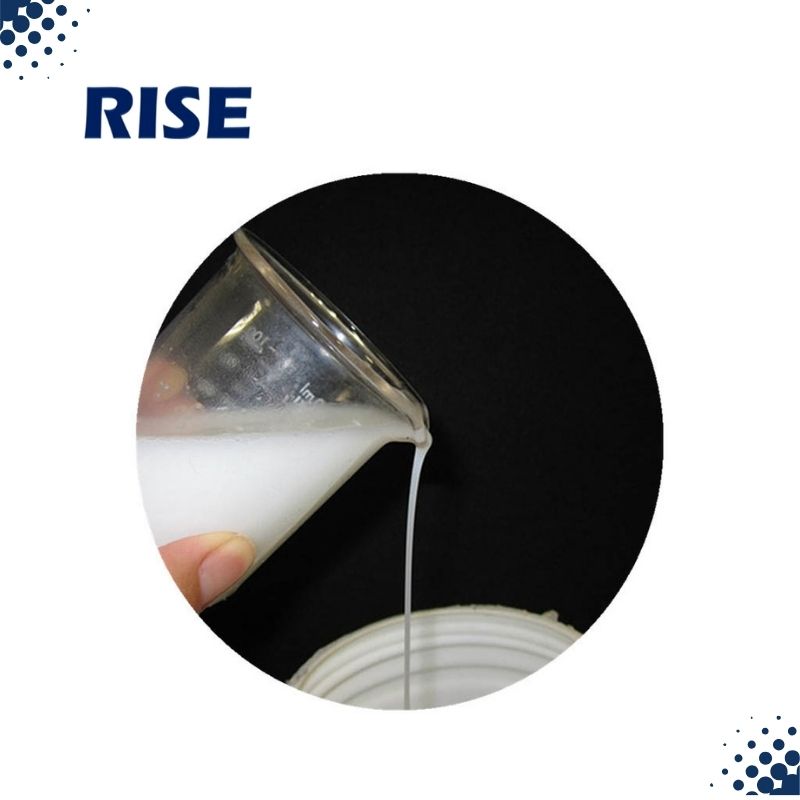

Product introduction

RISE glutamic acid fermentation defoamer is composed of polydimethylsiloxane, food emulsifier, dispersant, purified water, etc. The Glutamic acid food grade antifoaming agent overcomes the shortcomings of ordinary silicone defoamer, such as poor high temperature resistance and short foam suppression time , can meet the requirements of foam control throughout the fermentation cycle.

Product parameters

| Product name | Glutamic Acid Defoamer |

| Brand Name | RISE |

| Model Number | AF7530 |

| Purity | 30% |

| Appearance | white emulsion/transparent liquid/light yellow liquid |

| PH | 6.0-8.0 |

| Packing | 25kg 200kg 1000kg |

| Storage | 12 months |

| Certification | ISO9001/ISO14001/45001 |

| EINECS No | 9006-65-9 |

Usage and Precautions

1.Addition: According to different use systems, the addition amount of defoamer can be 0.05%-0.3%, and the addition amount is determined according to specific conditions;

2.Packing: This product is packed in 25/200/1000KG plastic drums;

3.Storage: Sealed and stored in a cool, ventilated and dry place indoors. Before use, the container should be strictly sealed after use. About 25℃, the shelf life is 12 months

4.Transportation: This product should be sealed well during transportation to prevent the ingress of impurities such as moisture, strong alkali, strong acid, rainwater, etc.

Package

25kg, 200kg, 1 ton/ barrel available

Our advantage

As a professional defoamer manufacturer, we can provide personalized customization for paint, coating, ink, forging, molding, agrochemical, petroleum, chemical, sewage treatment, concrete building protection, power plant fume desulfurization, textile, printing and dyeing, papermaking and other industries and other interface treatment solutions, providing high-efficiency defoamers and various defoamers with excellent special properties.

At this stage, we cooperates with Liaoning Anshan Qicai Chemical Co., Ltd. to provide sewage defoamer; cooperates with Liaoning Dalian Guangtaiyuan Environmental Protection Technology Co., Ltd. to provide landfill leachate defoamer; cooperates with a number of power plants to provide desulfurization defoamer; and Shantui Construction Machinery Co., Ltd. cooperates to provide cleaning agents and rust inhibitors. In 2019, the company became the designated supplier of special chemicals such as the National Energy Group, and its products cover many fields of many companies.

In the future, Rise will still put technological innovation and service innovation at the top of the company's development, provide customers with cost-effective solutions, and become a sustainable and trustworthy professional technology company.

Looking forward to working with you

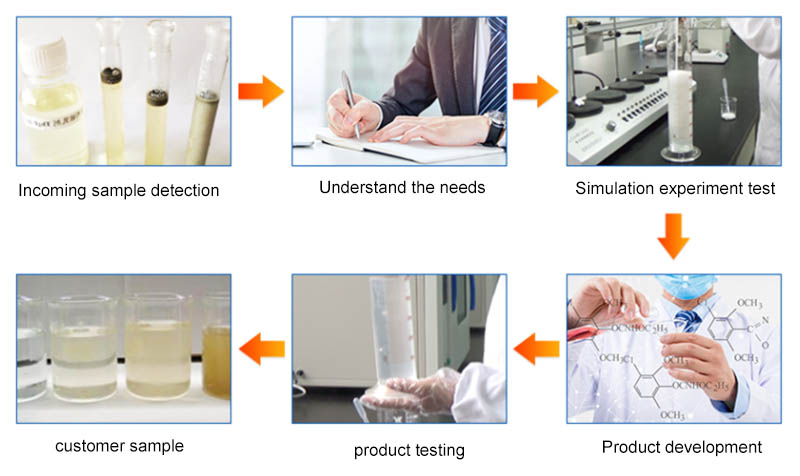

We provide comprehensive customer service, if our regular product model specifications can not meet your needs, we can customize products for you. We have a professional technical research and development team with several years of experience in the field of defoaming agents. We can customize products according to customers' specifications.

If you have any questions after picking up or during use, please do not hesitate to contact us. We will provide professional technical guidance. We look forward to working with you in the near future as we expand our business globally.