Oil And Gas Separation Defoamer

- RISE

- Liaoning, China

- 7days

- 50mt/Month

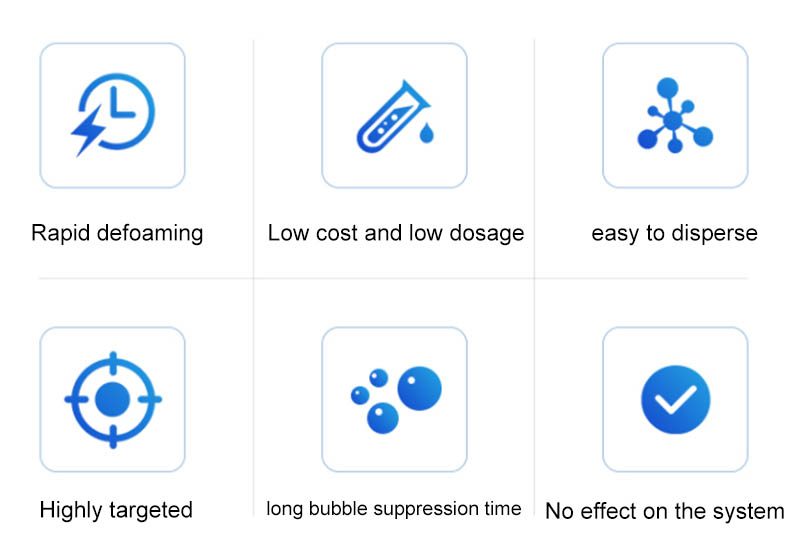

*GOOD DISPERSION

*FAST AND LONG-LASTING ANTIFOAM AGENT

*HIGH STABILITY DEFOAMER

*GOOD HEAT RESISTANCE, DOES NOT AFFECT SYSTEM OPERATION

*LESS ADDITION, HIGH COST PERFORMANCE

*EFFECTIVELY IMPROVE THE QUALITY OF OIL PRODUCTION

Oil And Gas Separation Defoamer

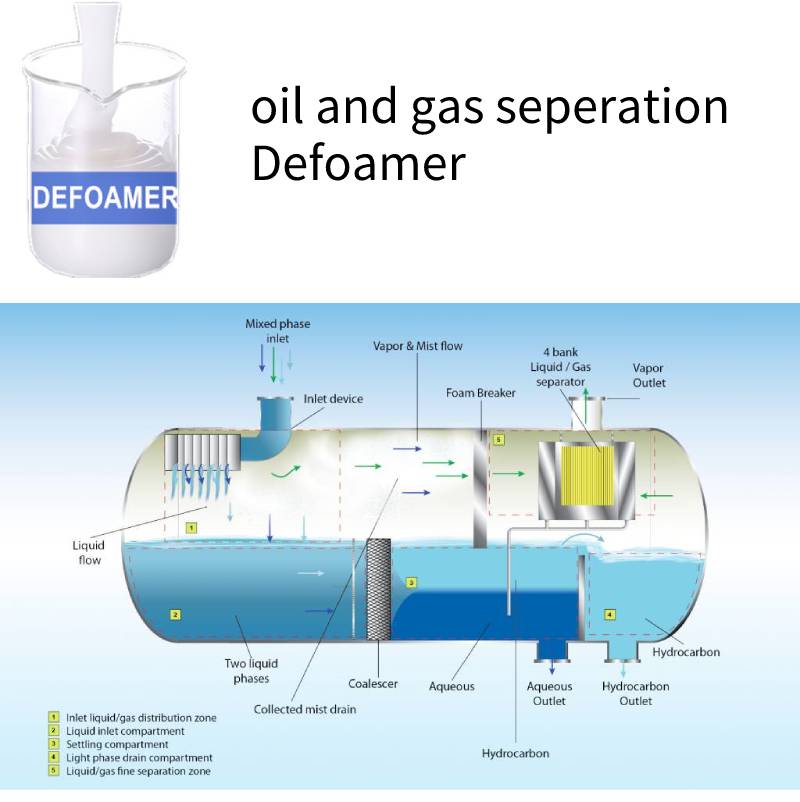

Causes of foaming in oil and gas separation

1. During the separation of oil and gas, the pressure and temperature decrease and increase to varying degrees, resulting in foaming.

2. The influence of surrounding environmental factors, resulting in blistering.

3. Substances in the oil-air mixture react chemically, resulting in foaming.

The hazards of oil and gas separation foaming

1. The foam in crude oil is relatively stable, and it is often too late to separate, or in order to maintain the separation effect, the production capacity of the separator must be reduced.

2. When the bubbles increase to a certain value, it will slow down the production process.

3. During canning, ship loading, and tanker loading, foaming affects measurement and affects loading efficiency.

Application of Oil and gas separation defoamer

The oil and gas separation defoamer has extensive applications across a variety of petrochemical production procedures. Oil and gas separation defoamer is employed to eliminate and inhibit foam within oilfield drilling mud, during the oil refining process or in the oilfield operations related to oil and gas separation, oil and gas gathering and transportation, delayed coking, natural gas extraction, as well as in the production of emulsified asphalt.

Product introduction for oil and gas separation defoamer

RISE Oil and gas separation defoamer is specially developed for the problem of foaming in the process of oil and gas separation and oil and gas gathering and transportation. The defoamer has excellent dispersibility, defoaming and anti-foaming properties, fast defoaming speed and long anti- foaming time.

Oil and gas separation antifoam chemical has good foam suppression effect on various heavy oils and light oils. The antifoaming agent has good stability and good compatibility with solvents, is an efficient defoaming agent chemical.

Product parameters for oil and gas separation defoamer

| Product name | Oil and gas separation defoamer |

| EINECS No | 9006-65-9 |

| Model Number | AF-1434 |

| Purity | 30% |

| CAS No | 9036-19-5 |

| Brand Name | RISE |

| PH | 6.0-8.0 |

| Appearance | white emulsion / transparent liquid |

| Packing | 25kg 200kg 1000kg |

| Certification | ISO9001/ISO14001/45001 |

| Storage | 1 year |

Usage and Precautions for oil and gas separation defoamer

Addition Guidelines: The quantity of defoamer to be added varies according to the specific use systems. Generally, it falls within the range of 0.05% to 0.3%. However, the exact amount needs to be carefully determined based on the unique requirements and conditions of each application.

Packaging Details: Our product comes packaged in plastic drums available in three standard sizes: 25KG, 200KG, and 1000KG. This variety of packaging options is designed to meet different usage and storage needs.

Storage Requirements: For optimal preservation, the product should be stored indoors in a location that is cool, well - ventilated, and dry. It is crucial to ensure that the container is tightly sealed both before use and immediately after each use. Under normal storage conditions, specifically at around 25℃, the product has a shelf life of 12 months.

Transportation Precautions: During transportation, the utmost care must be taken to keep the product well - sealed. This is to prevent any potential entry of impurities such as moisture, strong alkalis, strong acids, and rainwater, which could compromise the quality and effectiveness of the defoamer.

Package for oil and gas separation defoamer

25kg, 200kg, 1 ton/ barrel available

Our advantage

Since 2004, RISE Chemical Company has consistently provided high-quality, tailor-made foam control solutions for the most challenging client needs. RISE defoamer help solve all of these challenges efficiently and effectively. Whatever your application, the chances are that we have a chemical solution that will improve the efficiency of your process or the performance of your product.

With our extensive formulary and expertise in multiple applications, RISE Chemical Company is able to serve a wide variety of industries, including water treatment, paper and pulp, oil and gas, chemical industry, steel cleaning, automobile, electric power, adhesives, and many more.Our products are sold to the Middle East, Europe, America, Southeast Asia, Russia, Brazil and many other countries and regions. Provide personalized foam control solutions for many industries, provide various excellent defoamer and special properties chemical .

Looking forward to working with you

RISE Chemical has extensive experience with antifoam in multiple industries,please contact our foam control team to get recommendations for specific foam-control solutions.

FREE OIL AND GAS SEPARATION DEFOAMER SAMPLE.